BENDING

Hydraulic Bending Machine Manufacturer

ProBend ULTRA

Where precision intelligence meets power

Proteck’s ProBend Ultra series of Servo-Hybrid press brakes deliver industry leading performance along with unparalleled energy efficiency. Bending precision and repeatability are both greatly enhanced with these ‘run cool’ press brakes. Support systems such as sheet followers, sheet alignment detection, hydraulic tool clamping make the machines versatile and productive. Quality is assured with the most advanced press brake control available.

Available formats:

| Size | 2.5 m, 3 m and 4 m bend lengths |

| Press Force | Up to 220 Tons |

| Back Gauging | 4, 5 and 6 Axis |

| Accessories | Bending Aids, Angle Measurement |

ProBend MERIT

The new benchmark in bending performance

The ProBend Merit series of brakes are workhorse machines for production shops that run high volume workloads and require minimum maintenance machines that deliver precision and productivity, day after day. The ‘O’ frame concept of these machines minimize shop floor footprint and provide full width bending to full depth. The hydraulic system is power managed to run miserly on energy . The RA Standard Control provides real-time 3D bend simulation and operator guidance.

Available formats:

| Size | 2.5 m, 3 m and 4 m bend lengths |

| Press Force | 85, 110, 170 Tons |

| Back Gauging | 2 and 4 Axis |

| Options | Hydraulic Tool Clamp, CNC options |

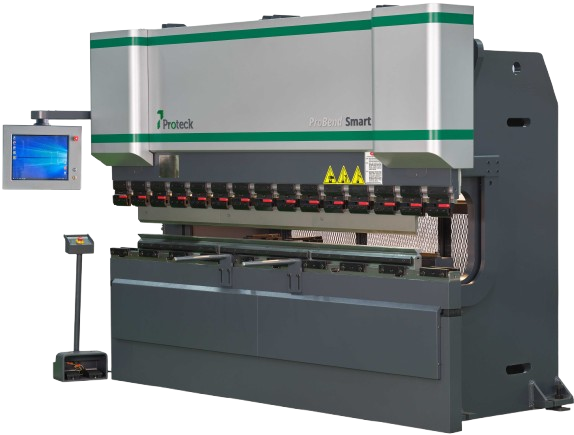

ProBend SMART

Minimum Maintenance, High Productivity

The ProBend Smart series of brakes are built on the Merit platform. These machines are intended for production shops that run medium volume workloads and require minimum maintenance machines that deliver precision and productivity, day after day. The ‘O’ frame concept of these machines minimize shop floor footprint and provide full width bending to full depth. The RA Lite Control provides an easy to use interface with operator guidance.

Available formats:

| Sizes | 2.5 m, 3 m and 4 m bend lengths |

| Press Force | 85, 110, 170 Tons |

| Back Gauging | 2 and 4 Axis |

ProBend HF

The heavy duty, super size work horse

The ProBend HF series of brakes are high press force machines with bending widths upto 6 meters and press force upto 400 tons. The heavy duty ‘C’ frame concept of these machines minimize deflection and ae optimised with FE analysis. The hydraulic system is power managed to run miserly on energy. The RA Standard Control provides real-time 3D bend simulation and operator guidance.

Available formats:

| Sizes | 4 m and 6 m bend lengths |

| Press Force | 220, 320, 400 Tons |

| Back Gauging | 2 and 4 Axis |

| Options | Hydraulic Tool Clamp, CNC options |

ProBend E-SMART

The Smart way to precision and productivty

The ProBend E-Smart brakes are all electric servo motor driven machines for production of small and medium sized parts requiring bending force less than 60 tons. These machines deliver the highest precision and repeatability besides the highest bending productivity, day after day. These machines minimize shop floor footprint and provide bending lengths upto 1.5 m. The all-servo drive system runs extremely economically on energy .

Available formats:

| Sizes | 1 m and 1.5 m bend lengths |

| Press Force | 30, 40 Tons |

| Back Gauging | 4 Axis |

| Options | Quick Tool Clamp, CNC options |